Amendments 1 and 2 to AS/NZS 5033 in 2018 made it possible to use an isolator integrated into an inverter without the need for additional adjacent DC isolators, so long as the integrated isolator met certain requirements (clause 4.3.5.1, 4.3.5.2, 4.3.3.3.1 etc.). This was a win for the industry as it results in fewer points of failure, fewer enclosures that can suffer from water ingress and allows part of the isolator fit off to be done by machines in a very accurate way as it is enclosed in the IP-rated case of the inverter.

In the unlikely event that an arc starts in the integrated isolator, the burning would be confined to the enclosed inverter case, meaning that the arc is less likely to track out of the enclosure due to cables splitting to go through plugs or individual cable entry holes. Not only does this result in safer installations, it also reduces system costs related to components and labour.

To be sure that an integrated isolator is compliant to be installed on its own, an installer must be satisfied of four things:

Obtain a “self-declaration” from the inverter manufacturer stating that the integrated isolator complies with all relevant clauses of AS/NZS 5033. Each of the clauses should be listed.

Make sure the inverter has “separate screening” from touch on the PV side of the integrated isolator that is within the same external enclosure as the other components of the PCE (Amendment 1, clause 4.4.1.2). With the cover off the inverter, in most cases it will be metal sheet or mesh protecting the isolator terminals from stray fingers or metallic tools. Manufacturer’s instructions to disconnect any external DC plugs do not meet this requirement.

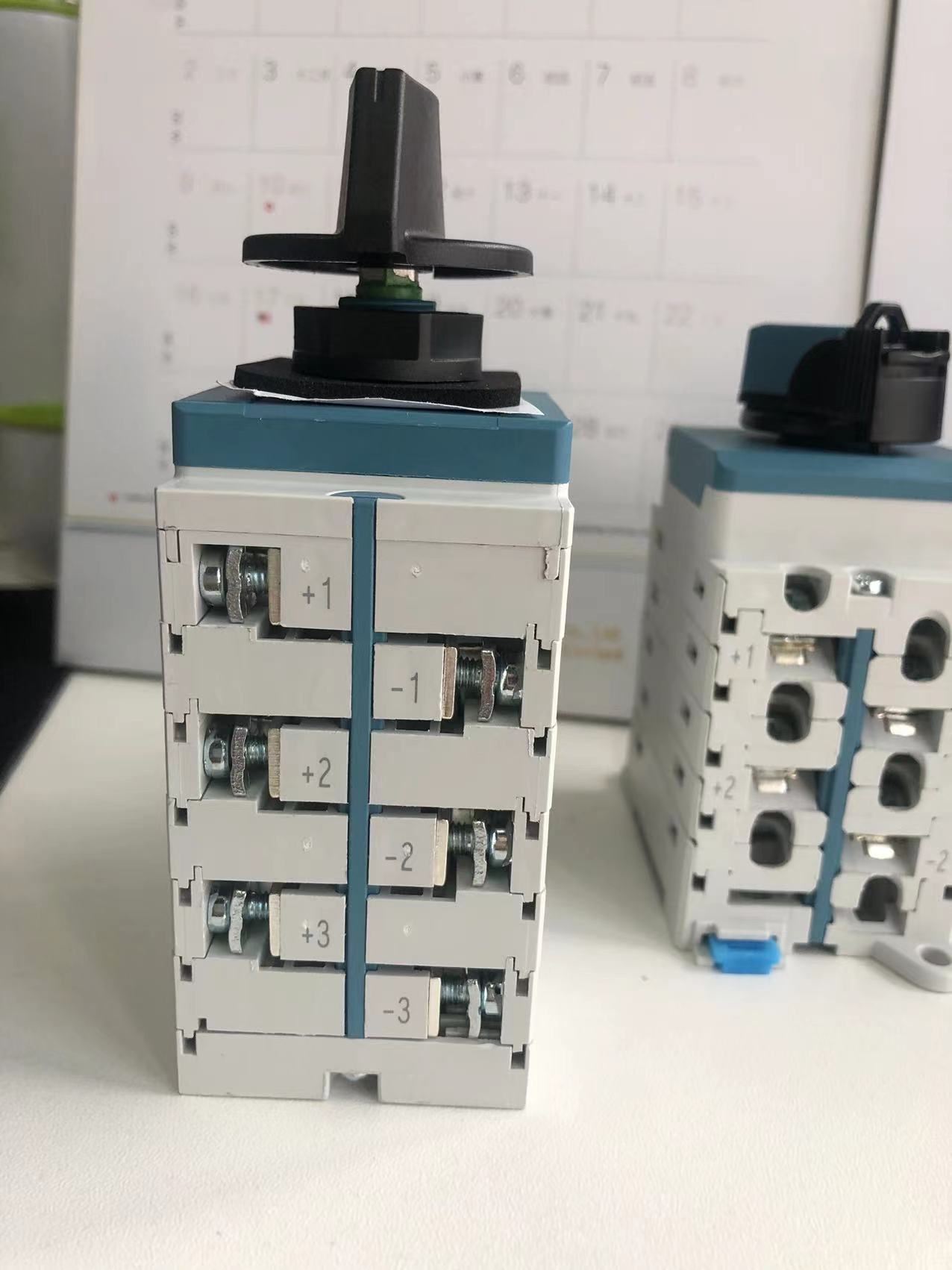

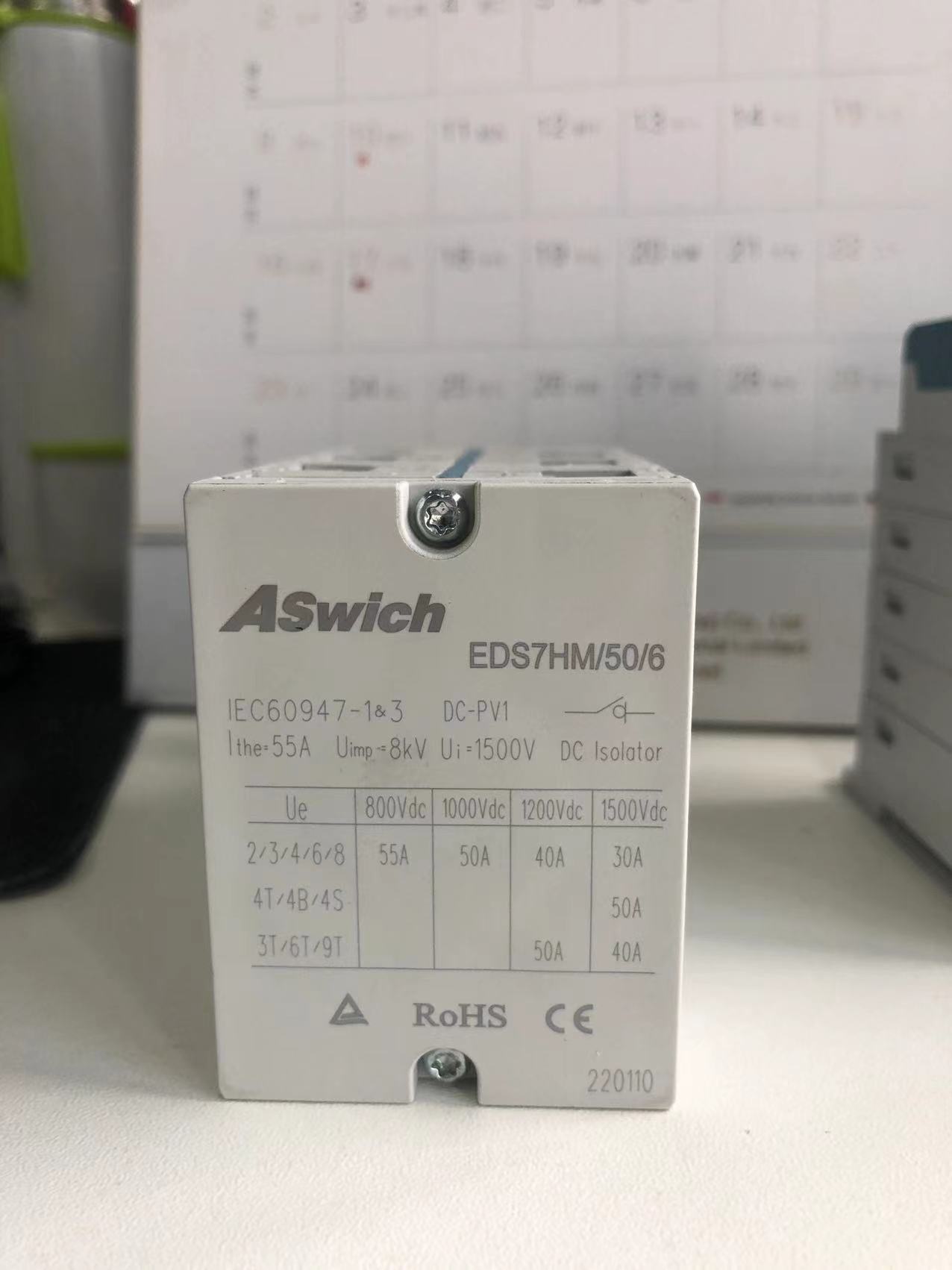

The integrated isolator must be correctly rated as per AS/NZS 5033 for the PV array/s being fed through it (Amendment 2, clause 4.3.5.1). An installer rates the integrated isolator in the same way they do for all of their DC isolators: obtain the spec sheet from the manufacturer and size it using 1.25 times the current (examples can be found in Appendix I of Amendment 2, and the Clean Energy Council has also held a webinar on this issue titled “Changes to DC isolator requirements” and a Toolbox Talk called “Sizing DC disconnectors”).

Find the integrated isolator model on the Electrical Regulatory Authorities Council (ERAC) list at https://equipment.erac.gov.au/Public/, which is a requirement for most states and territories other than NSW. It identifies that the product has been tested and is compliant as Equipment Class Level 3, Equipment Sub-class DC isolator.

If the inverter or isolator you intend to install has not been tested and passed the requirements to be on the ERAC list, it is not suitable to install without adjacent DC isolators.

While manufacturer self-declarations are a good first step, it should be noted that AS/NZS 5033 is an install standard, meaning that when an installer signs off that they have met all requirements of the relevant standards, they are effectively signing off that they know that the integrated isolator is compliant. Therefore, if an inspector audits a system and identifies that the integrated isolator is in fact not compliant to the standard, the onus is on the installer to clarify or rectify the installation.